The cooling water enters the mold temperature machine through the filter, is heated by the heater to the required temperature of the mold, and then is transported to the mold by the water pump. After returning from the mold, the high-temperature water is heated by the heater and sent to the mold. In this way, it circulates back and forth to achieve the effect of temperature control.

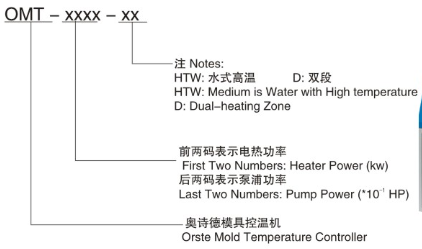

189-4860-6110 / 0769-82020256 Online consultationNaming Principle

Features

Equipped with the design of one week automatic start/stop timer, screen can be converted between Chinese and English.

P. I. D. multi-stage temperature control system can maintain a mold temperature with an accuracy of ±1oC.

Adopts high efficiency water cycle pump, which can meet the demands of temperature control for precise molds and mold loop with minor diameter to achieve precise temperature control and high efficiency heat exchange. Pump inside adopts stainless steel to avoid explosion.

Multiple safety devices including power reverse phase protection, pump overload protection, overheat protection and low level protection that can automatically detect abnormal performance and indicate this via visible alarm.

For standard OMT-W, the heating temperature can reach 120oC, while for OMT-HTW, it can reach 160oC.

Equipped with high pressure protection, safety pressure relieving, automatic water supplying and air exhausting.

For OMT-W, direct cooling is adopted, while for OMT-HTW, indirect cooling is adopted. Automatic water supplying device ensures fast heat exchange.

Unique design of seperating the electric cabinet and heating chamber can protect the electrical components and significantly expand the service life of the machine.

Application

OMT-W series water heaters are widely used in the production of plastic product. They are mainly applied to heat up the mold and maintain temperature, also they can be used in other similar fields. Through the principle of heat exchange, they can shorten the product mold cycle and improve production efficiency.

Function Scheme

Water enter into mold temp. controller through the filter, and then be heated to the required temp. of the mold. The high temp. water is conveyed to the mold to maintain its heat by pump, then the water returned from the mold is heated and pressured to the mold to continue the circulation, thus achieving the effect of temp. control.

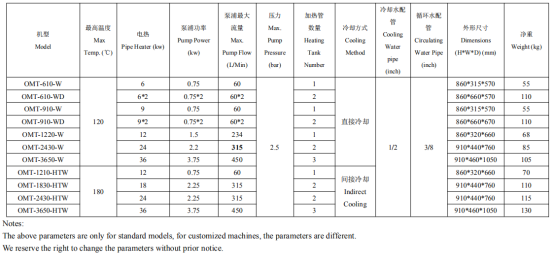

Parameters